10 Must-Follow Regulatory Compliance Checks for Storing Biological and Cell Therapy Samples in 2025

In the rapidly evolving landscape of cell and gene therapies, maintaining regulatory compliance for biological sample storage isn’t just good practice, it’s essential for patient safety, product integrity, and business continuity. As regulatory frameworks continue to evolve in response to technological advancements and emerging therapies, organizations must stay vigilant about compliance requirements and how to implement a validated storage system.

The stakes couldn’t be higher. A single compliance failure can result in compromised patient safety, regulatory actions, financial penalties, and irreparable damage to reputation. For cell therapy CDMOs, biobanks, and other patient-centric organizations, understanding and implementing these critical compliance checks is non-negotiable.

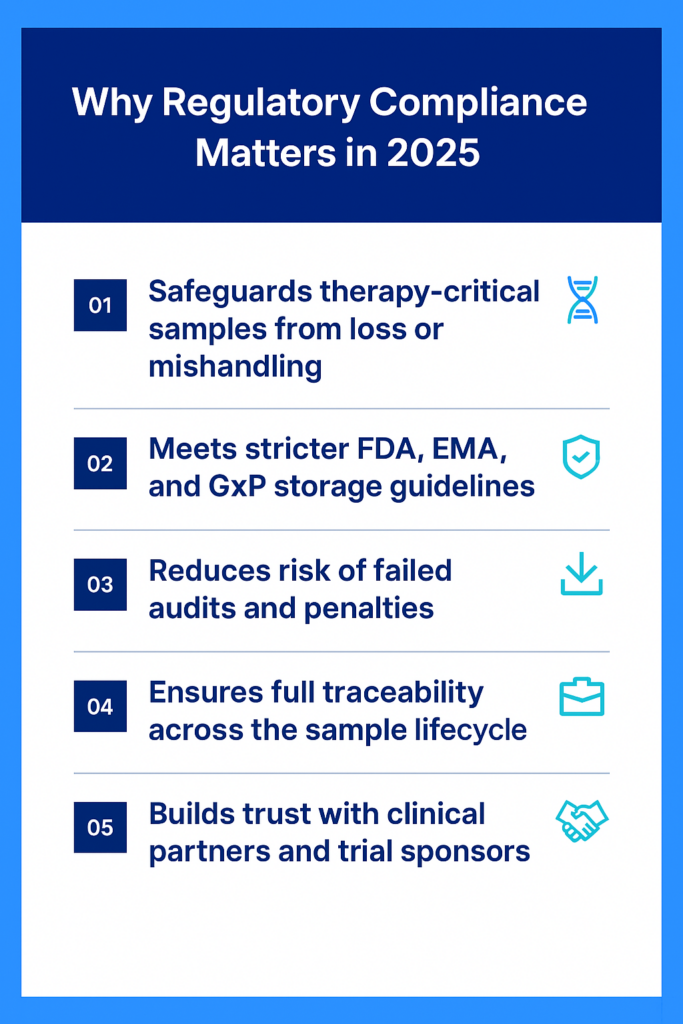

Why Regulatory Compliance Matters More Than Ever in 2025

The cell and gene therapy sector has seen exponential growth, with over 400 therapies in late-stage clinical trials and dozens receiving regulatory approval. This surge has brought increased scrutiny from regulatory bodies worldwide, driving a need for scalable, audit-ready storage systems, with the FDA, EMA, and other authorities.

Recent data reveals that specimen loss rates hover around 0.002%, which may seem negligible until translated to real numbers thousands of mishandled samples monthly across healthcare systems. Each lost or compromised sample represents not just data but potentially life-saving therapy for a patient.

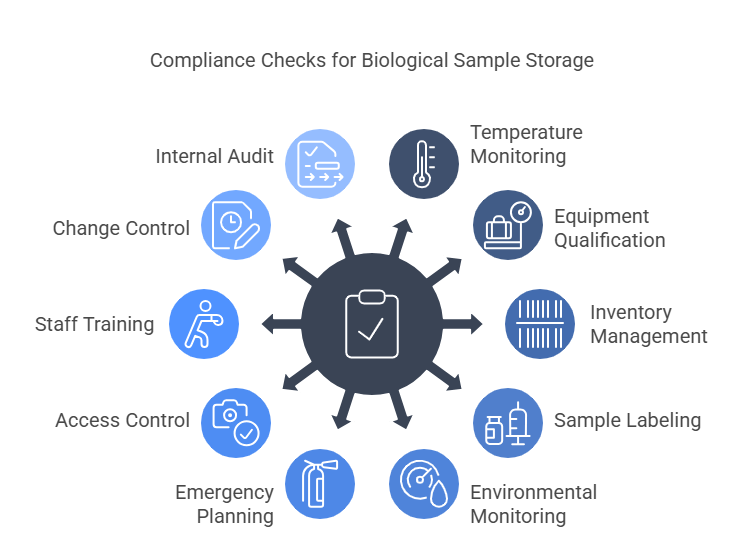

The 10 Essential Compliance Checks for Biological Sample Storage

1. Temperature Monitoring and Documentation Systems

Regulatory requirement: Continuous temperature monitoring with alert systems and complete data records.

Regulatory bodies require uninterrupted temperature monitoring for all storage environments. Modern compliance standards necessitate:

- Real-time temperature monitoring with 24/7 alert capabilities

- Automated documentation of temperature readings at specified intervals

- Backup monitoring systems in case of primary system failure

- Validation of monitoring systems according to 21 CFR Part 11 requirements

- Comprehensive records of temperature excursions with corresponding corrective actions

Compliance tip: Implement electronic monitoring systems like the one we deployed for NYBC that automatically document temperatures and generate alerts when parameters deviate from acceptable ranges.

2. Equipment Qualification and Calibration

Regulatory requirement: Regular equipment qualification (IQ/OQ/PQ) and instrument calibration with documented evidence.

Storage equipment must undergo rigorous qualification processes:

- Installation Qualification (IQ) to verify correct installation

- Operational Qualification (OQ) to confirm function per specifications

- Performance Qualification (PQ) to demonstrate consistent performance

- Regular calibration of all measurement devices traceable to national standards

- Detailed maintenance logs and calibration certificates accessible for inspections

Compliance tip: Develop a master calibration schedule with automated reminders and documentation requirements to ensure no equipment is overlooked.

3. Validated Inventory Management System

Regulatory requirement: Electronic inventory systems validated for their intended use with complete audit trails.

Your inventory system forms the backbone of sample tracking and must:

- Maintain complete Chain of Custody and Chain of Identity records

- Track sample locations with precise coordinates

- Document all sample movements with timestamps and user identification

- Include validated backup and recovery procedures

- Support barcode or RFID technology for accurate sample identification

- Comply with electronic record requirements (21 CFR Part 11)

Compliance tip: Choose inventory management systems specifically designed for GMP environments and validated for cell therapy applications.

4. Sample Labeling and Identification Controls

Regulatory requirement: Unique identification systems resistant to storage conditions with redundant verification processes.

Sample labels must:

- Withstand ultra-low temperatures (including liquid nitrogen for cryogenic storage)

- Include human-readable and machine-readable (barcode/RFID) information

- Contain required information (unique ID, collection date, product details)

- Incorporate redundancy to prevent misidentification

- Remain intact throughout the sample lifecycle

Compliance tip: Implement dual identification methods and regular integrity checks for labels, especially for samples stored in extreme conditions.

5. Environmental Monitoring Program

Regulatory requirement: Comprehensive monitoring of storage environments beyond just temperature.

A compliant environmental monitoring program includes:

- Humidity monitoring and control

- Particle and contamination monitoring in clean areas

- Microbial monitoring according to GMP requirements

- Regular environmental testing with trend analysis

- Documented response protocols for deviations

Compliance tip: Establish environmental monitoring schedules based on risk assessments of different storage areas and sample types.

6. Emergency Response and Contingency Planning

Regulatory requirement: Documented emergency procedures with regular testing and staff training.

Robust contingency plans must address:

- Power failures with backup generator systems

- Equipment malfunctions with redundant storage options

- Natural disasters and facility emergencies

- Sample rescue and transfer protocols

- Communication procedures during emergencies

- Regular drills and simulations to test preparedness

Compliance tip: Conduct annual emergency simulation exercises and update contingency plans based on the results and changing regulatory guidance.

7. Access Control and Security Systems

Regulatory requirement: Restricted access to biological materials with documentation of all interactions.

Implement multi-layered security systems including:

- Physical access restrictions (key cards, biometric systems)

- Electronic access logs for all storage areas

- Video surveillance of critical storage zones

- User authentication for all sample transactions

- Regular security audits and penetration testing

Compliance tip: Establish different access levels based on job functions and maintain detailed logs of who accessed what samples and when.

8. Staff Training and Competency Assessment

Regulatory requirement: Documented training on SOPs with regular competency verification.

Comprehensive training programs must:

- Cover all relevant SOPs for sample handling and storage

- Include regulatory requirements and compliance rationale

- Verify competency through practical assessments

- Document all training activities and outcomes

- Implement regular refresher training

- Maintain training records for regulatory inspections

Compliance tip: Develop role-based training matrices that align with CAPA and deviation response systems that clearly define required competencies for each position involved in sample management.

9. Change Control and Documentation Management

Regulatory requirement: Formalized change control processes with impact assessments and documentation.

Effective change control systems must:

- Document all changes to equipment, processes, or systems

- Include risk assessments before implementation

- Maintain version control for all procedures and documents

- Record approvals from authorized personnel

- Ensure traceability of all process modifications

Compliance tip: Implement electronic document management systems that enforce approval workflows and maintain audit trails of all changes.

10. Internal Audit Program

Regulatory requirement: Regular internal audits with documented corrective and preventive actions.

Establish a robust audit program that:

- Schedules regular audits of all aspects of sample storage

- Uses qualified auditors familiar with regulatory requirements

- Documents all findings and observations

- Tracks corrective and preventive actions

- Verifies the effectiveness of implemented changes

- Prepares the organization for regulatory inspections

Compliance tip: Develop an audit calendar and audit-ready infrastructure that simplifies inspections and ensures coverage of all critical areas at least annually, with more frequent audits for high-risk processes.

Meeting Compliance Challenges with Modern Solutions

Maintaining compliance with these requirements presents significant challenges, particularly as sample volumes increase and regulations evolve. Traditional paper-based systems and manual processes simply cannot keep pace with modern compliance demands.

Advanced software solutions specifically designed for biological sample management, like PragLife’s Storage Inventory system, offer comprehensive tools to address these compliance challenges. These systems provide real-time monitoring, automated documentation, integrated barcode functionality, and robust audit trails – all critical components for maintaining regulatory compliance.

Looking Ahead: Emerging Regulatory Trends

As we move further into 2025, several regulatory trends are emerging that will impact sample storage compliance:

- Increased focus on data integrity and electronic records

- Greater emphasis on end-to-end traceability (Chain of Identity and Chain of Custody)

- Harmonization of requirements across international regulatory agencies

- Enhanced requirements for risk management in sample storage

- Growing scrutiny of cybersecurity measures for digital systems

Organizations that proactively address these emerging areas will be better positioned to maintain compliance and avoid regulatory issues.

Conclusion

Regulatory compliance for biological and cell therapy sample storage requires a systematic approach encompassing equipment, processes, documentation, and personnel. By implementing these 10 critical compliance checks, organizations can safeguard sample integrity, ensure patient safety, and meet regulatory expectations.

As the regulatory landscape continues to evolve, maintaining compliance demands vigilance, adaptability, and the right technological tools. The organizations that excel will be those that view compliance not as a burden but as an opportunity to enhance quality, build trust, and ultimately deliver better outcomes for patients. For more information on how PragLife’s Storage Inventory system can help your organization maintain regulatory compliance, contact our team of experts.